Related news

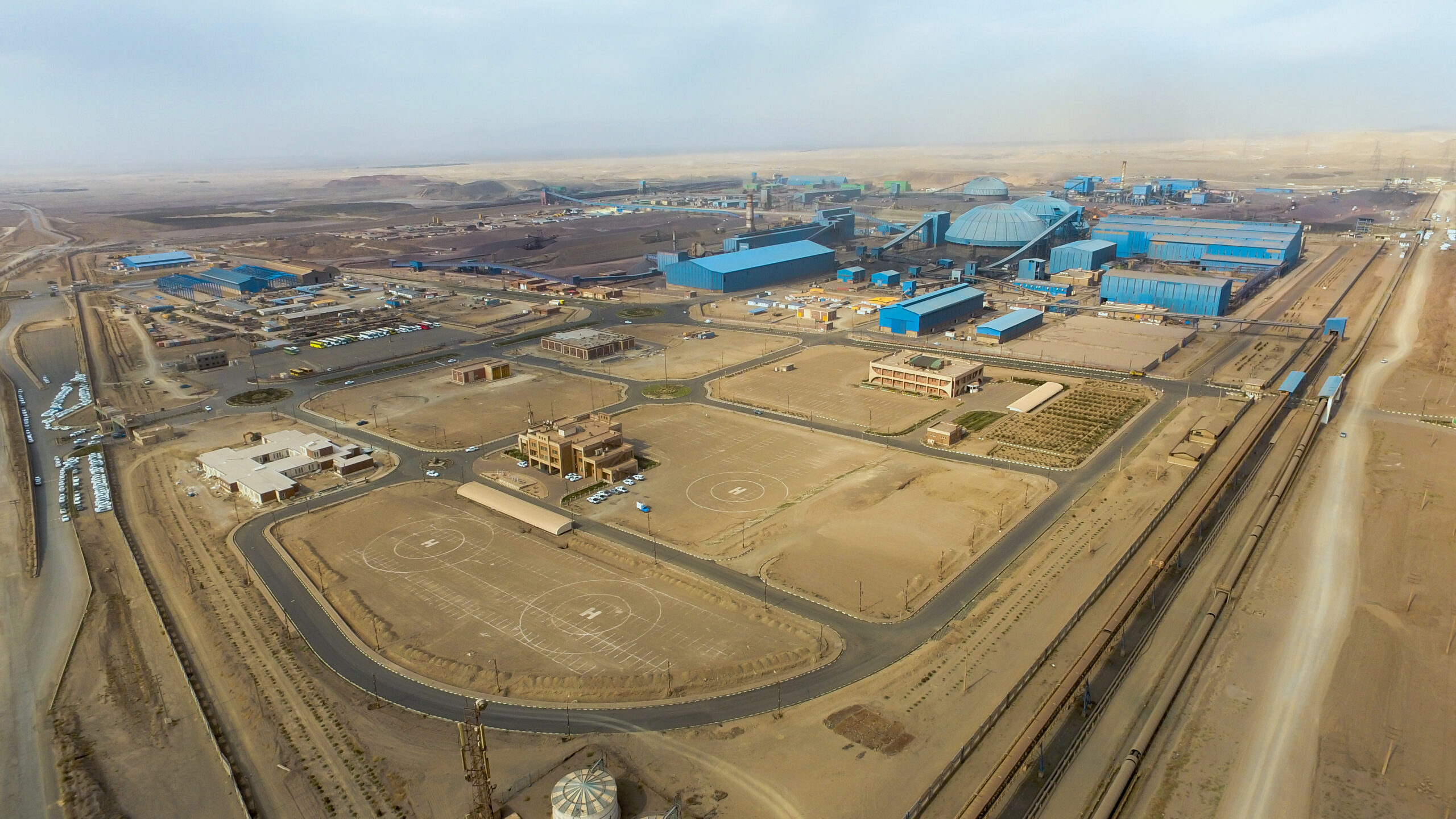

The Strategic Role of Sangan-Khorasan Steel Mining Industries Company (SSMIC), the Largest Industrial Unit in Eastern Iran, in Raw Material Supply

Raw material supply is the first and most critical step in any industry, and disruptions in this process can significantly impact the entire sector. The steel industry is no exception, as each stage in the steel value chain serves as raw material for the next. The initial steps of this supply chain occur upstream, involving iron ore extraction, concentrate production, and pelletizing—the key areas in which Sangan-Khorasan Steel Mining Industries Company (SSMIC) operates. Within less than a decade of its establishment, SSMIC has made significant strides in supplying raw materials, particularly pellets, to meet the country’s demands, with a special focus on supporting its parent company, Mobarakeh Steel Company. The company’s outlined vision further promises a growing role in securing raw materials for the steel industry in Iran.

The steel industry plays a fundamental role in reducing Iran’s reliance on oil revenues, meeting downstream industries’ needs, and advancing the non-oil economy. However, ensuring a stable supply of raw materials is a critical prerequisite for this goal. Without sufficient attention, this issue could become the Achilles’ heel of Iran’s steel sector, potentially undermining its development advantages.

As one of the most significant contributors to the upstream steel supply chain, Sangan-Khorasan Steel Mining Industries Company (SSMIC) operates two major plants: a concentrate production facility and a pelletizing plant, each with a capacity of 5 million tons per year. The company plays a vital role in securing a stable supply of pellets for Mobarakeh Steel Company—the largest steel producer in the Middle East—and for the country’s steel industry in general.

SSMIC’s key advantages include access to one of the largest iron ore reserves in the Middle East, boasting a grade of 43%, proximity to the region’s largest iron ore mines, and access to railway transportation. These strategic advantages enhance the company’s ability to fulfill its mission in the steel supply chain.

Upward Growth Trend

SSMIC was established with the core objectives of producing high-quality pellets, completing the value chain for Mobarakeh Steel Group, and contributing to the economic, social, and environmental development of northeastern Iran. In less than a decade, it has established itself as a major supplier of pellets in Iran.

In the first seven months of the current year, Sangan-Khorasan Steel Mining Industries Company (SSMIC) produced approximately 3.216 million tons of pellets and 2.57 million tons of concentrate, selling 3.05 million tons of pellets. Compared to the same period last year, pellet production increased by 17%, and sales surged by 43%. These results indicate that the company is on track to achieve its full production capacity this year, significantly contributing to a stable supply of raw materials, particularly for Mobarakeh Steel Company and the country at large.

SSMIC has continued its upward trajectory, selling over 3.8 million tons of products in the first nine months of this year—an increase of 31% compared to the same period last year. Since its inception, the company has supplied nearly 20 million tons of pellets to Mobarakeh Steel and its subsidiaries. However, SSMIC remains committed to expanding its role in the steel value chain and increasing its market share. To achieve this, the company is planning to boost its annual pellet production capacity from 5 million to 7.5 million tons and to construct a hematite concentrate plant with a capacity of 2.5 million tons per year.

Statistics from the Iranian Steel Producers Association indicate that Iran’s total pellet production in the first half of the current year stood at 31.92 million tons, compared to 33.396 million tons in the same period last year. During this time, SSMIC’s share of the country’s pellet production grew from 6.8% to 7.2%. This upward trend is expected to accelerate with the realization of SSMIC’s ongoing expansion projects.

A Strategic Initiative

The primary driver behind SSMIC’s pellet production growth is its increased concentrate output, enabled by access to the largest iron ore mines in eastern Iran. This growth also reflects the company’s strong adaptability in maintaining production despite challenges such as energy shortages, exchange rate fluctuations, and supply chain disruptions.

Despite severe energy restrictions in July and August, SSMIC increased pellet production by over 30% and 20%, respectively, compared to the same months last year. This achievement was made possible through precise planning, optimized energy management, and guaranteed electricity procurement. Additionally, the company’s strong sales performance highlights its ability to meet customer demands with high-quality products, driving further market interest in its offerings.

While Iran has long been recognized for its abundant mineral resources, decades of extensive extraction of high-grade magnetite ores have raised concerns about future shortages. Experts warn that Iran may soon face a scarcity of high-quality iron ore, potentially transitioning from a resource-rich country to an importer of raw materials.

To address this challenge, SSMIC has leveraged the expertise of knowledge-based companies to develop innovative solutions for converting low-grade hematite ores into magnetite. This forward-thinking approach is expected to ensure a stable raw material supply, sustain production, and strengthen SSMIC’s role in the country’s steel industry.

To further support this goal, SSMIC is constructing Iran’s largest hematite concentrate plant with an annual capacity of 2.5 million tons. This initiative marks a significant step toward securing a stable raw material supply, enhancing production capacity, and bringing the company closer to achieving its 1404 vision of becoming the largest mining and steel company in northeastern Iran. Under this vision, SSMIC aims to produce 7.5 million tons of both concentrate and pellets annually, reinforcing its strategic importance in Iran’s steel industry.